The company devotes itself to the backlight display module field. by continuously making technological innovation and strengthening integrated production capacity, it continuously creates high-quality products with leading technology, excellent quality and comprehensive services. With many years of mold design and manufacturing experience and adopting Japan high-precision mold processing equipment, the company keeps pave with customer needs, and values product portfolio development, so as to provide customers with one-stop professional products and technical solutions.

-

01Development & Design

Structural Design

Mold Design

Optical Design

Electrical Performance Design

Tooling & Fixture Design

-

02Analysis

Optical Analysis

Mold Flow Analysis

Automation Solutions

-

03Metal Manufacturing

High Pressure Mold

Forming Mold

Stamping Mold

Tooling & Fixture Manufacturing

-

04Lean Production

Injection Molding

Sheet Metal Stamping

SMT

Injection Molding

Assembly

Full Lamination

Inspection & Testing

-

05Test Solutions & Validation

Environmental Testing

Electrical Performance

Mechanical Performance

Durable Performance

-

06Electronics Programming

System/Architecture Design & Validation

Electronics Design, Development & Verification

-

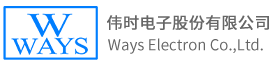

Backlight Design & Development

Backlight Design & Development -

Smart Surface Process Structure

Smart Surface Process Structure -

Aerial Imaging Process Structure

Aerial Imaging Process Structure -

IML Technical Capability

IML Technical Capability -

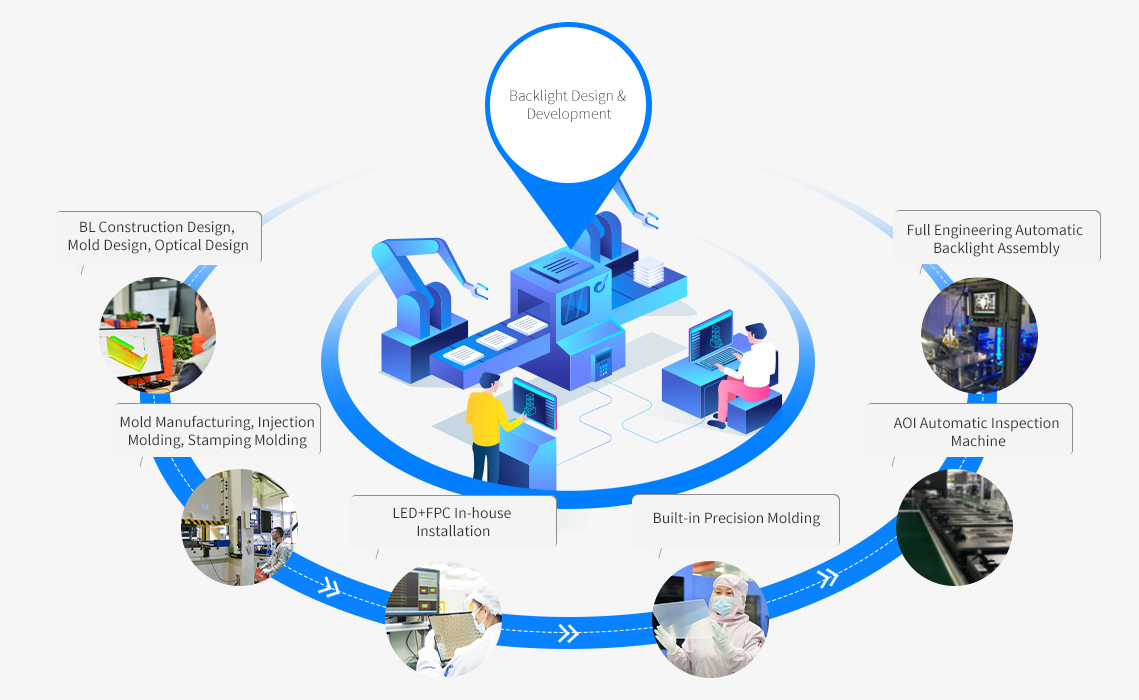

Module Lamination Capacity

Module Lamination Capacity -

Mini LED Backlight Display

Mini LED Backlight Display

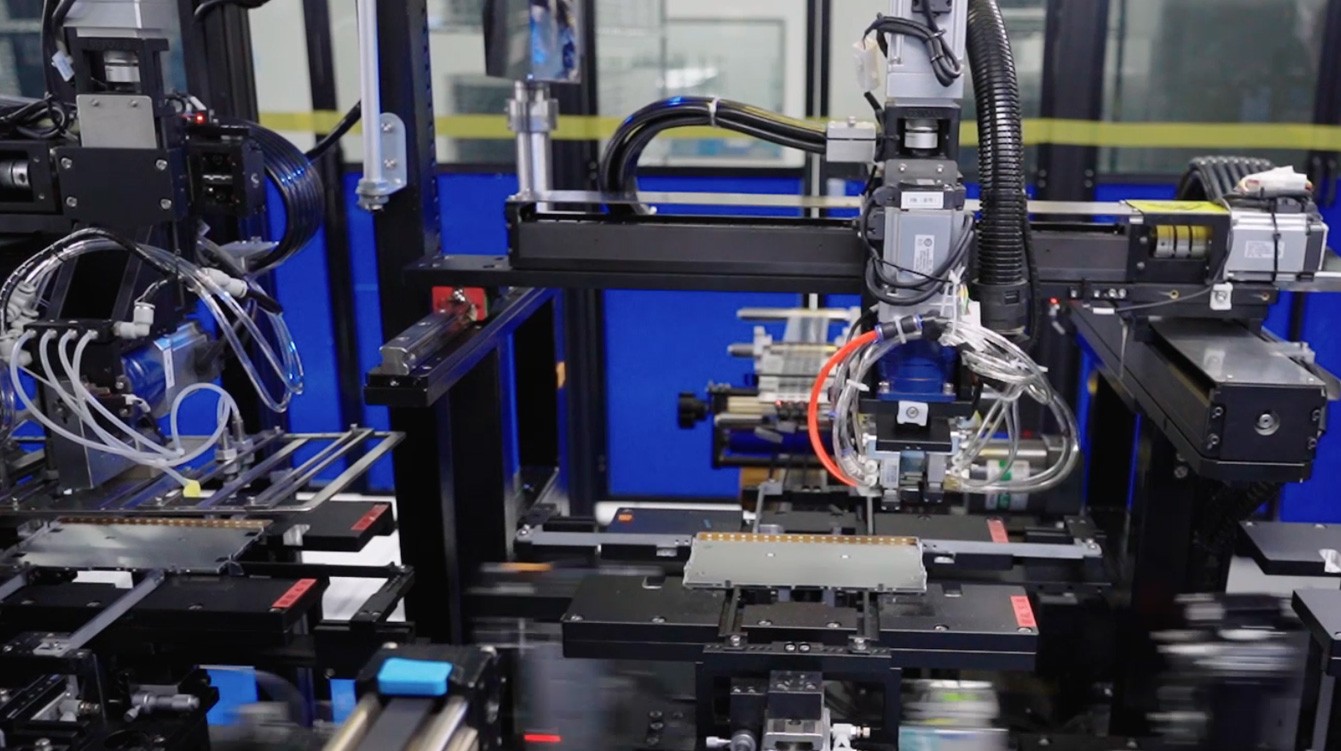

Equipped with 4 CNC machining centers;

Equipped with Makino CNC machines with high-precision and high speed;

Equipped with 4 sets of EDM spark machines and 6 sets of Mitsubishi and Makino slow wire cutters.

More than 20 grinding and milling machines

Familiar with the design standards of all kinds of mold design standards